What are Encapsulated O-Rings?

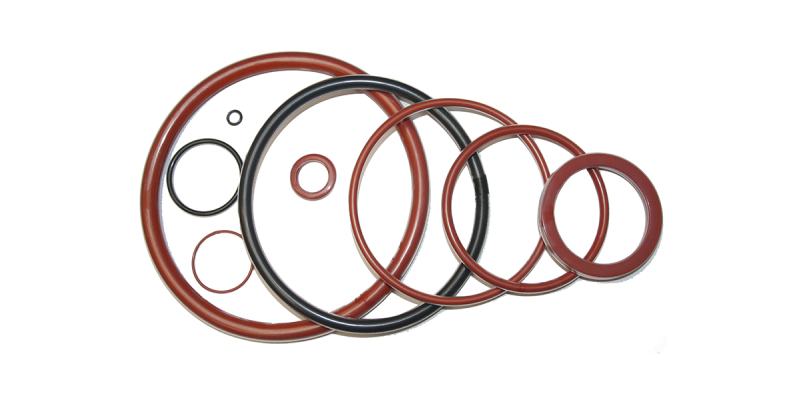

What are O-Rings?

July 9, 2019

Interesting facts to know about the rubber industry

July 16, 2019Encapsulated O-Rings are specially modeled seals that help in solving the common problems of the industries. Sometimes, you may also require temperature and chemical defiance of PTFE, but they do not have enough flexibility that is needed for compressed fluid sealing. You may also opt for flexible elastomeric, but they are not the type of materials that can be dealt with chemicals.

Encapsulated O-Rings are known to be the best in the world of industries. The outer part of the jacket is fashioned from Teflon making the seal highly resistant to corrosion and gives thermal stability as well. The inner part provides elasticity and compression.

Encapsulated O-Rings have two different types

It has two varied groups of the core which help them to adjust for different types of applications. The two types of encapsulated 0-Rings are as follows.

- Solid Core – They are the common encapsulated O-Rings which have a core either made from silicone energizer or FKM, also popularly called as Viton. The cores of FKM have a great compression set and excellent elasticity. The silicone core shares the same a feature like that of the FKM, the only point it differs is it is softer while resisting heat of high standard. Silicone core is recommended for cold temperatures as they retain their flexibility.

- Hollow Core – Though no core can be compared to that of the silicone and FKM, they sure come with some compromise level. Hollow core is mostly used for fragile applications.

FEP or PFA is the common material for outer jacket core (H2) - PFA – PFA is Perfluoroalkoxycopolymer. It resists highly to corrosive chemicals which include the naphtha, alcohol, petroleum, aromatic solvents and acid. The compression set is mostly low but they have high strength in mechanical terms and improved defiance to stress and cracking.

- FEP – FEP is Fluorinated Ethylene Propylene. They have similar qualities like that of the PFA. The friction has a low coefficient, resist chemicals and the compression set is low. They are a little weak mechanically and have a shorter life span. They have been approved by the FDA and are mostly low in cost price.

Encapsulated O-Rings are popular because of its advantages

They are very popular and have excellent defiance to all kinds of media. They can work in a vast temperature range. They are also FDA approved making it suitable for drugs and food processing applications. They are known for their perfect hygiene quality resisting contamination from outside materials and are the perfect solution for petrochemical and chemical industries.

Encapsulated O-Rings has few limitations

The outer jacket is the thing making it vulnerable for scratches, making it nonusable to applications that contain powders or abrasive slurries. High dynamic systems are also not a good choice for Encapsulated O-Rings.